Industrial parts and accessories

We invite you to cooperate and familiarize yourself with our latest catalogue.

more

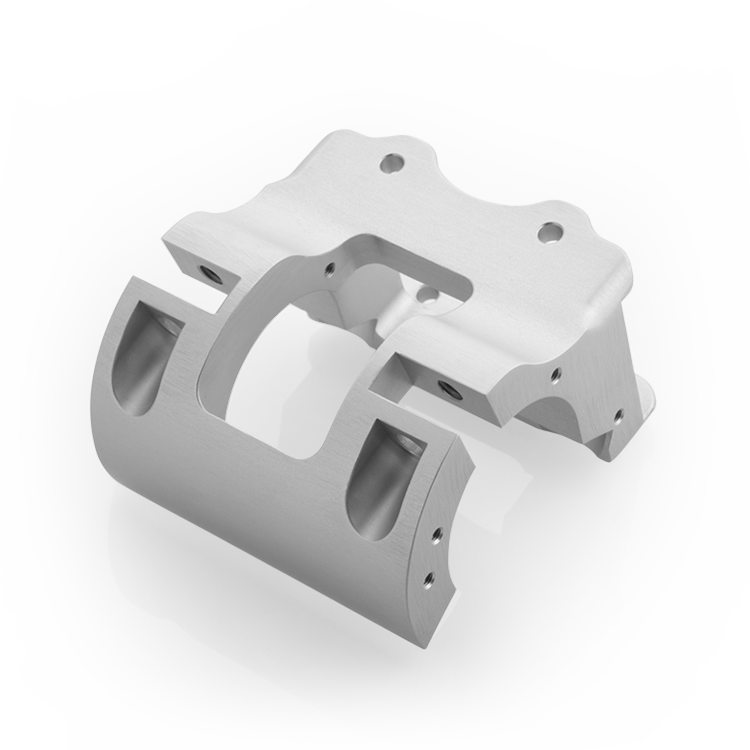

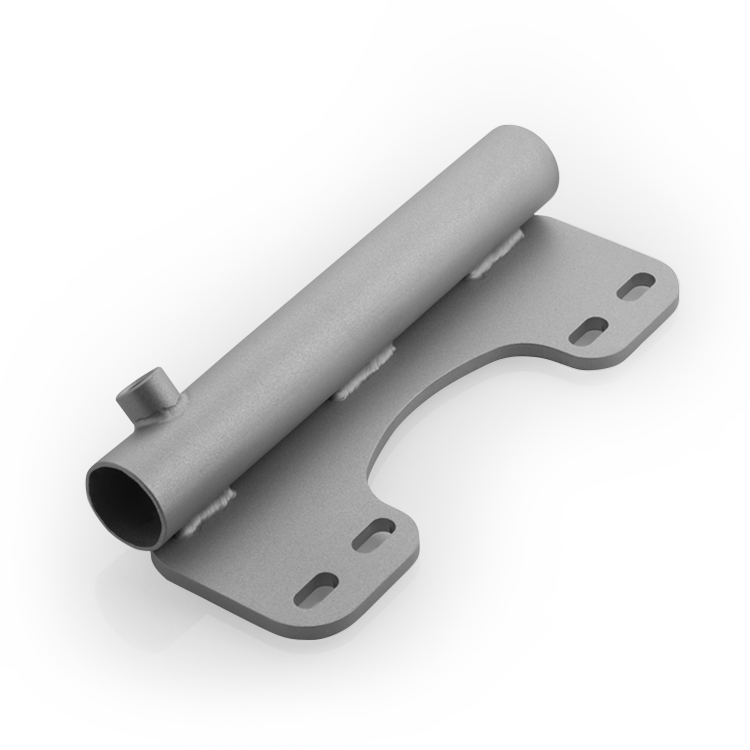

Turning

and milling

Modern CNC lathes, turning and milling centers, 3-axis and 5-axis machining centers and experienced specialists.

more

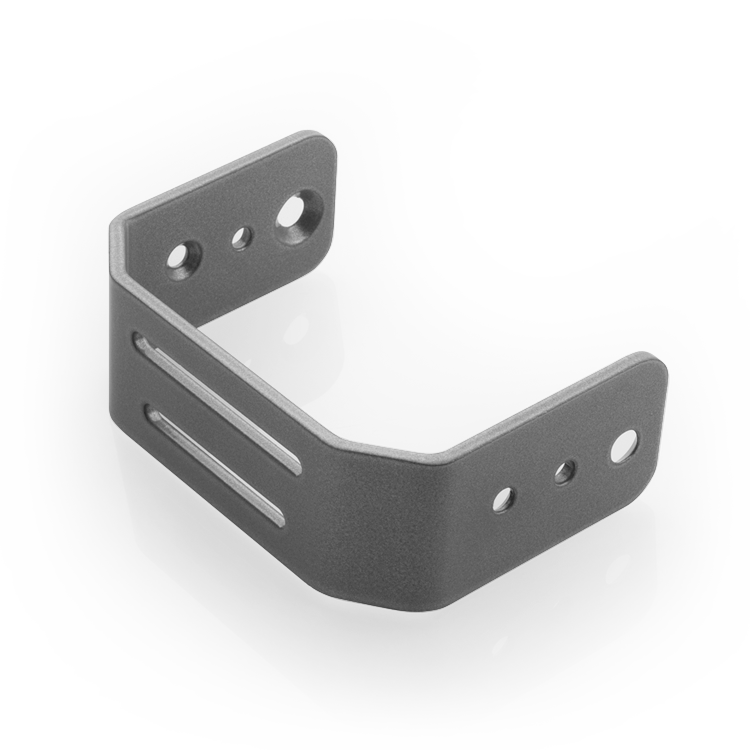

Bending and sheet metal working

Our range of services extends from the manufacture of parts through the welding of individual parts to the assembly of complete housings.

more

Welded

elements

The welding work is carried out by certified specialist companies. Upon request, the quality is documented and ensured by tests.

more

Surface

treatment

Through our network of competent surface specialists, we offer you a wide range of finishing processes.

more

Thermoforming

Termo-

formowanie

Thermoforming is a forming process in which a three-dimensional component is formed from plastic sheets with the aid of a tool under the action of heat.

more

Assembling

Best quality with short turnaround times is our claim – we like to be measured by it!

more

Processing

of wires and electrical harnesses

As part of its activity, Silesius offers finishing and preparation of electrical harnesses.

more